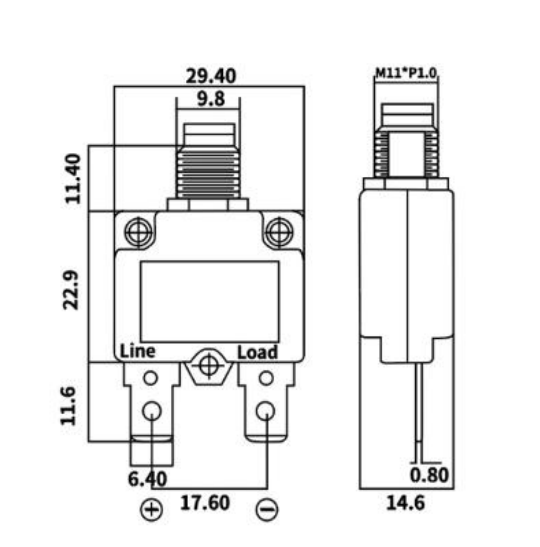

No matter what kind of control box you’re designing, it’s important to follow the established best practices of control box design . Some of the core principles of designing a great control box are as follows:

- Butyl rope caulk is also known for its excellent adhesion properties. Once applied, it forms a tight seal that effectively prevents water, air, and dust from entering the sealed area. This makes it an ideal solution for sealing gaps and cracks in windows, doors, and other surfaces where air or water infiltration is a concern.

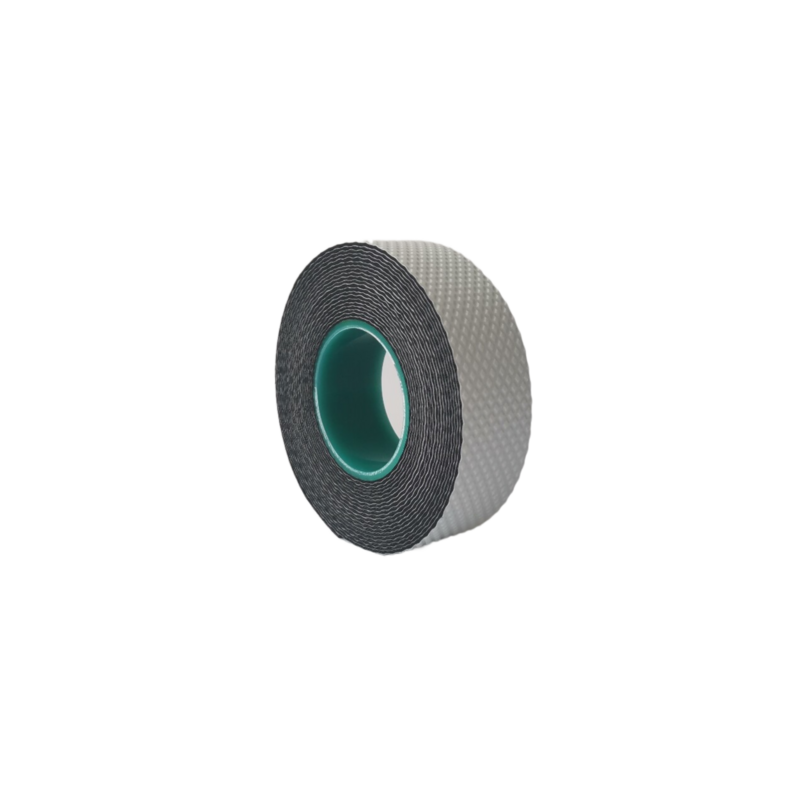

Linerless Insulating Rubber Tape

These sturdy containers protect electrical components from environmental hazards and serve as an orderly command center, facilitating the safe and efficient functioning of connected devices. Control boxes are integral to electrical infrastructure, whether nestled within the walls of a home, anchoring the operations of a bustling factory, or braving the elements in an outdoor setting.

Silicone tape is renowned for its waterproof properties. It is an ideal solution for sealing leaks in boats, outdoor equipment, or even temporarily fixing damaged gutters during heavy rain.

Moreover, its adhesive properties ensure a secure and long-lasting bond, even in extreme conditions, making it suitable for both indoor and outdoor applications Moreover, its adhesive properties ensure a secure and long-lasting bond, even in extreme conditions, making it suitable for both indoor and outdoor applications

Moreover, its adhesive properties ensure a secure and long-lasting bond, even in extreme conditions, making it suitable for both indoor and outdoor applications Moreover, its adhesive properties ensure a secure and long-lasting bond, even in extreme conditions, making it suitable for both indoor and outdoor applications arc proof tape.

arc proof tape.3M also makes an electrical tape made of silicone rubber for applications where Class “H” (180°C/356°F) temperatures are encountered i.e., silicone rubber cables.

Whether it's repairing leaks in roofs, plumbing systems, or even automotive applications, this tape can be swiftly wrapped around the affected area, instantly creating a watertight seal Whether it's repairing leaks in roofs, plumbing systems, or even automotive applications, this tape can be swiftly wrapped around the affected area, instantly creating a watertight seal

Whether it's repairing leaks in roofs, plumbing systems, or even automotive applications, this tape can be swiftly wrapped around the affected area, instantly creating a watertight seal Whether it's repairing leaks in roofs, plumbing systems, or even automotive applications, this tape can be swiftly wrapped around the affected area, instantly creating a watertight seal premium leakage repair waterproof sealant butyl rubber tape.

premium leakage repair waterproof sealant butyl rubber tape.In this post, we'll briefly explain why you would use a self-fusing electrical tape and the typical applications for them.

There are several reasons why butyl sealant tape is chosen over other sealing materials:

Another advantage of temporary floor marking tape is its ease of implementation. It requires little training or specialized tools to apply, making it accessible to all staff members. The tape can be easily cut to length and applied directly to the floor, allowing for quick adjustments as needs change. This flexibility is particularly beneficial in dynamic environments where layouts may frequently change.

One of the key characteristics of PVC black tape is its excellent electrical insulation properties. It is widely used in electrical work to insulate wires and connections, protecting against short circuits and enhancing safety. The tape is designed to withstand a range of temperatures and resist moisture, ensuring that it retains its adhesive properties and protective capabilities even in challenging environments. This makes it an essential material for electricians and technicians who require reliable tools to ensure the safety and efficacy of their work.

Butyl rubber is a heavy-duty adhesive that instantly adheres quickly and easily to most surfaces, even those like outside decks where moisture is a factor. Butyl tape is compatible with these surfaces:

In general, rubber based adhesives are not UV or oxidation resistant which is why they tend to be used predominantly in interior applications. Having said that, antioxidants and UV stabilizer packages can be added to the formulation to help mitigate these weaknesses. Some synthetic elastomers exhibit vastly improved UV stability over natural rubbers. Chemical resistance can also be problematic as is resistance to elevated service temperatures (typically 180- 200°F at the top end). The great strength of rubber-based adhesives is their wide formulation latitude. These adhesives can be compounded to be removable, repositionable, or extremely permanent. High strength foam bonding tapes can be made from rubber based adhesives or easily removable masking products can also be offered. Rubber based adhesive adhere to many surfaces including low surface energy plastics such as polypropylene and polyethylene. And to top it all off, rubber based adhesives are economical. They get the job done at a very fair price! Adhesive tapes made from rubber based adhesives have come a long way since Dr. Day’s first surgical tape and they still offer a cost-effective way to bond, seal, and protect.

Butyl seal tape is much easier to work with than the traditional sealants used for windows, so many people prefer to use it. It is incredibly supple and easy to bend and manipulate to the shape of the surface you’re using it on, making it ideal for installation on oddly-shaped windows and window frames.

flame proof tape. In vehicles, there are many components that generate heat and can potentially ignite a fire. By using flame proof tape to protect these components, manufacturers can reduce the risk of fires occurring in vehicles and improve overall safety.

Understanding the Control Box: A Comprehensive Guide

4. Electrical Insulation The primary function of red insulation tape is to provide electrical insulation. It can effectively cover exposed wires, preventing accidental contact and short circuits.

red insulation tape

automotive fabric tape. They can withstand extreme temperatures, UV radiation, and other environmental factors that can cause other types of tapes to degrade over time. This makes them a popular choice for use in outdoor applications, such as on the roofs and hoods of vehicles, where they can provide long-lasting protection against the elements.

automotive fabric tape. They can withstand extreme temperatures, UV radiation, and other environmental factors that can cause other types of tapes to degrade over time. This makes them a popular choice for use in outdoor applications, such as on the roofs and hoods of vehicles, where they can provide long-lasting protection against the elements.